Why do we use battery monitoring system?

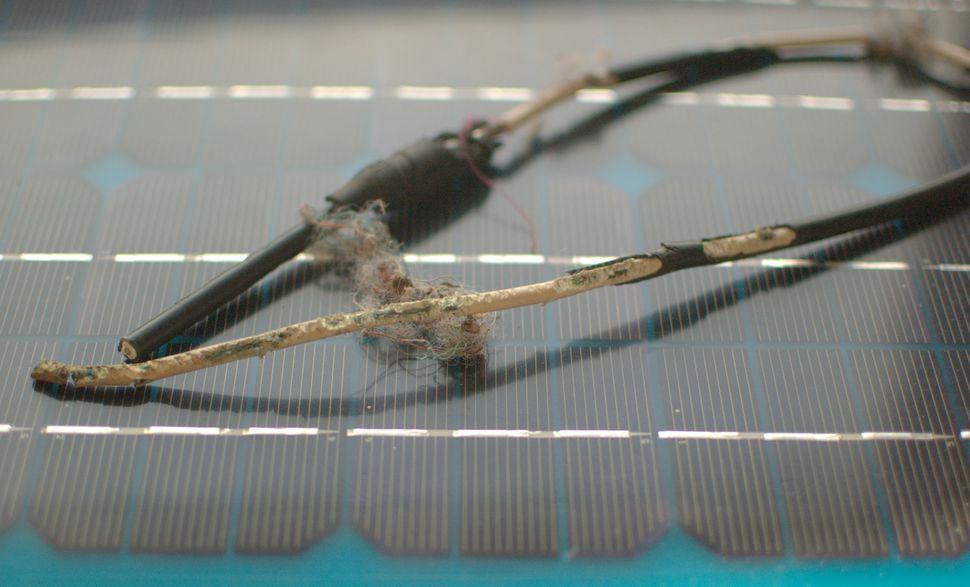

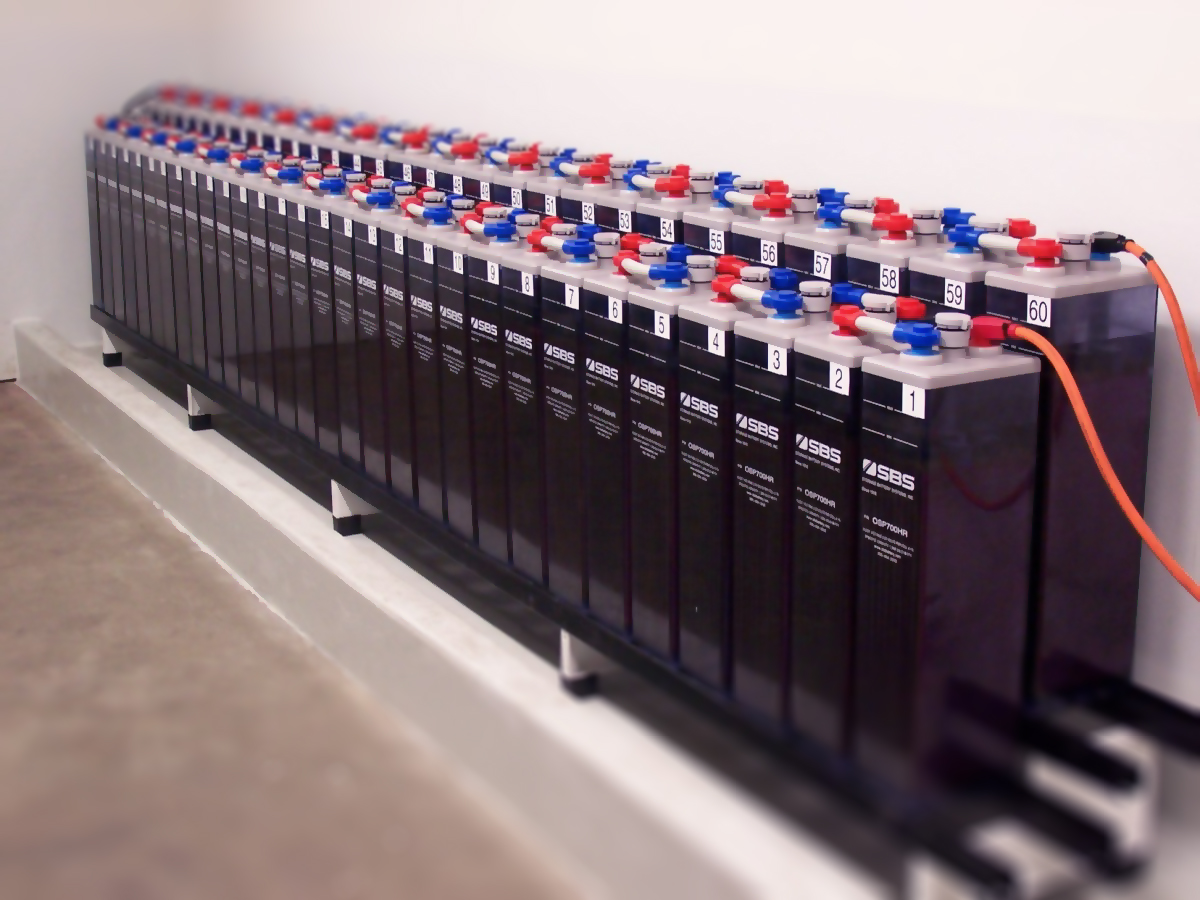

Continuous power is essential for organizations with critical applications. Stand by batteries provide the last line of defence against downtime. Without battery monitoring the true integrity and capacity of battery banks remains unknown.

Technology of battery monitoring has important impact on reliability and can be used to define the best strategy for service and replacement, resulting in a better level of protection for all applications. Continuous monitoring of internal resistance, voltage, current, temperature and changes during charge/ discharge cycling can specify degeneration of individual batteries prior to failure.

Our Battery Monitoring System

Intelligent battery status monitoring with predictive analytics and alert before its failure

Real-time Monitoring with high accuracy

Battery cells can be monitored individually

Automatic Online Load Test during float charge – no maintenance time

Secure installation

Scalable with modular design

Applications

- Solar Farm – Energy Storage – up to 2 MWH per system

- Telecom Industry 48 Vdc system – Network Nodes and BSC Centralized monitoring.

- Data Center – UPS backup battery – up to 1,920 battery blocks per system

Specifications : Solution BM-0204

Battery Monitoring Catalog 20180319

Battery Monitoring Catalog 20180319

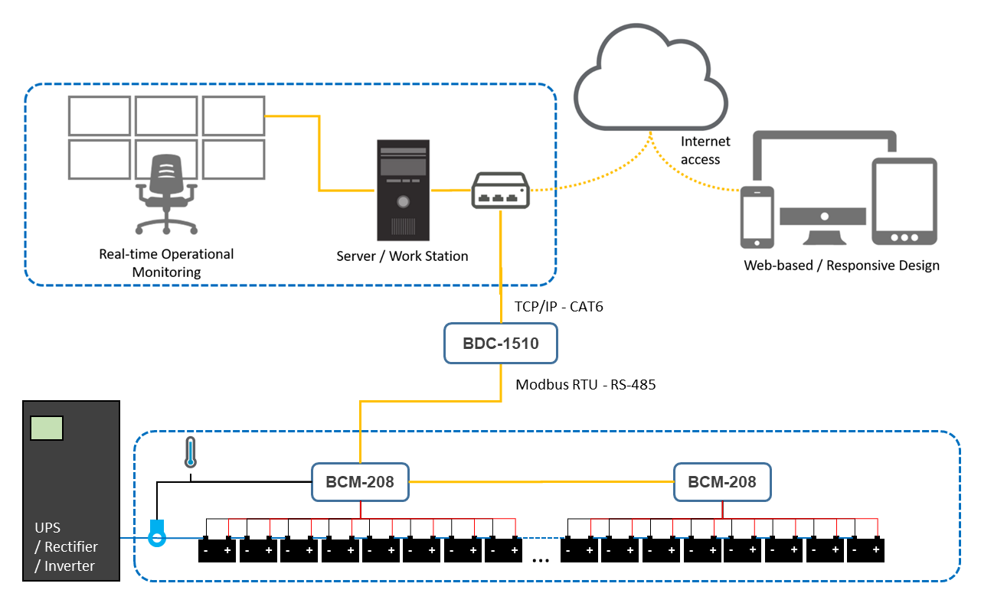

Battery monitoring solution for energy back-up batteries. Up to 240 batteries per single system and up to 1,920 batteries using additional server.

Real-time monitoring for individual cell voltage, ambient temperature and string current.

Automatic load test and battery health check by internal resistance.

Suitable for both Data Center and Telco with 48Vdc environment.

Web-based user interface and web-service API (JSON)

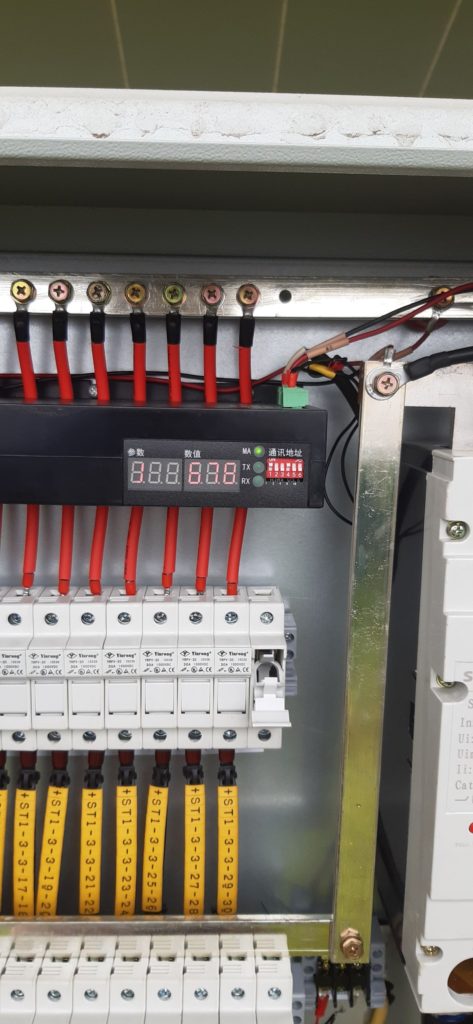

Battery Monitoring Module : model BCM-208

A BCM-208 is designed for individual battery cell voltage measurement.

Individually load test to check state of health (SoH) of each battery.

Float charge current and voltage monitoring.

No power consumed from monitored battery to avoid fully discharge that can cause the battery damages.

| BCM-208 : Specification |

| Voltage measurement range |

2 V – 12 V |

| Voltage accuracy |

+/- 0.1 % |

| Voltage resolution |

0.01 V |

| No. of Voltage channels |

8 Channels |

| No. of Current channels |

2 Channels |

| No. of Temperature channel |

1 Channel |

| Dry Contact Output 12V/1A |

1 Channel |

| Communication RS-485 with Modbus Protocol |

| Communication Response Time |

100 ms |

| Operating temperature |

-20 to 80 ºC |

| Operating humidity non-condensing 10 – 80% RH |

| Current Accuracy |

+/- 1% |

| Current Resolution |

0.1 A |

| Temp. measurement range |

0-80 ⁰C |

| Temperature accuracy |

+/- 2% |

| Temperature resolution |

0.1 ⁰C |

| Auto. Load Test is available for 7 – 300AH Battery |

| Auto. Load Test Schedulable up to 4 time/day |

| Powered from Power Supply |

12 – 48 Vdc |

| Power consumption |

2 W |

| Size 10x20x3 cm. Weight 760 g. |

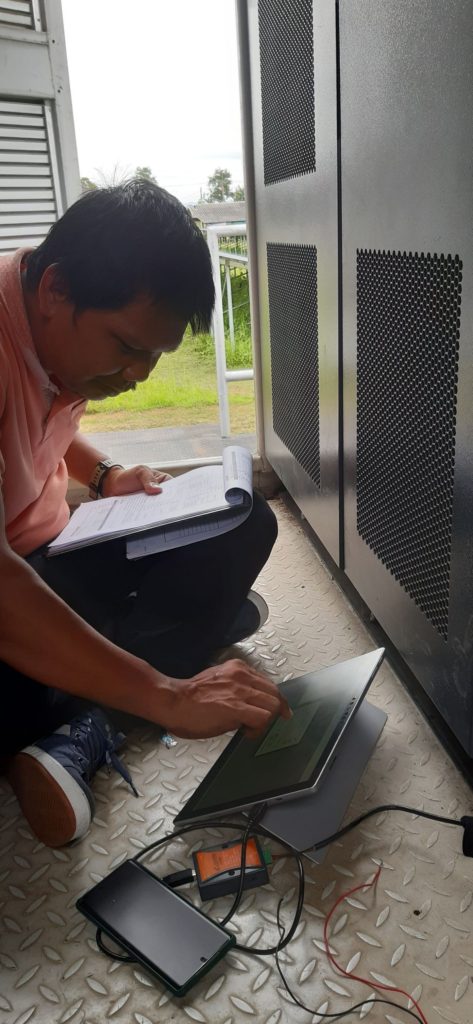

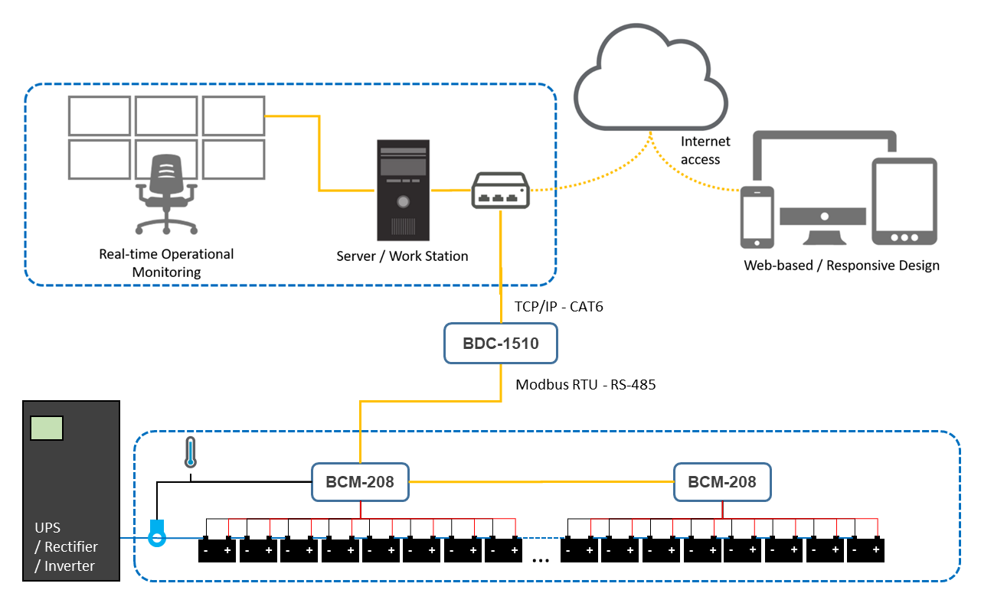

Data Collector Unit : model BDC-1015

A BDC-1015 Fanless Embedded system is used to collect voltage/temperature/current data from BCM-208 via RS485 ports.

BDC-1015 can be web server to let client computers to connect and display battery information via web-base UI and JSON API.

And also be a web client used to post data to cloud server.

| BDC-1015 : Specification |

Maximum number of connection to BCM-208 :

30 modules 240 Batteries (15 modules/bus) |

| No. of RS-485 Port |

2 ports |

| No. of Ethernet Port |

1 port |

| Web-service Interface |

JSON |

| Web-based User Interface |

HTML5 |

| Dry Contact Output 12V/1A |

2 Channels |

| Auxiliary Analog Input |

2 Channels |

| Operating temperature |

-20 to 80 ºC |

| Operating humidity non-condensing |

10 – 80% RH |

| Load Test Scheduling Configurable |

| Internal Resistance Data Logger |

| Solid State Current Load |

|

| SD Card Memory |

4 GB |

| OLED Display |

|

| Powered from Power Supply |

12 – 48 Vdc |

| Power consumption |

2 W |

| Size 10x20x3 cm. Weight 500 g. |

String Current & Temperature Module : model C8-200

A C8-200 is a module used to measure the string current and ambient temperature with hall effect current senor and temperature probe.

| C8-200 : Specification |

| Current Sensor |

|

| Current measurement range |

+/- 50 to 1000 A |

| Current Accuracy |

+/- 1% |

| Linearity |

1% |

| Insulation Voltage |

3000 Vdc |

| Operating Temperature |

-10°C ~ +80°C |

| Unit Weight |

90 g |

| Offset Voltage |

20mV |

| Hysteresis Error |

±10mV |

| Overload Capacity |

20 times |

| Response Time |

10uS |

| Thermal Drift |

500 ppm/°C |

| Power Consumption |

0.25 W |

| Temperature Sensor |

|

| Temperature measurement range |

0-80 ⁰C |

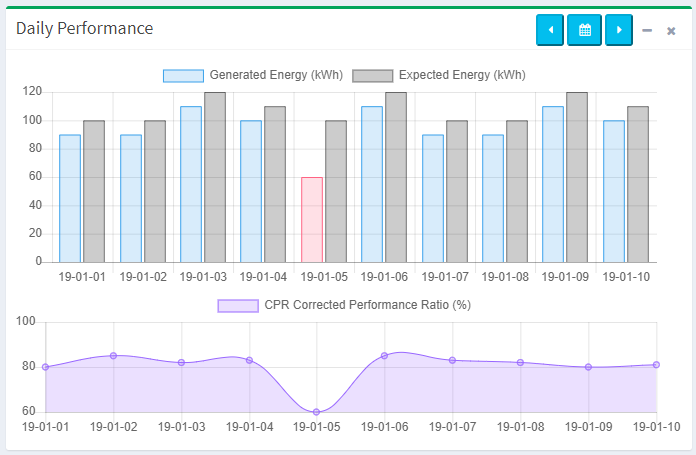

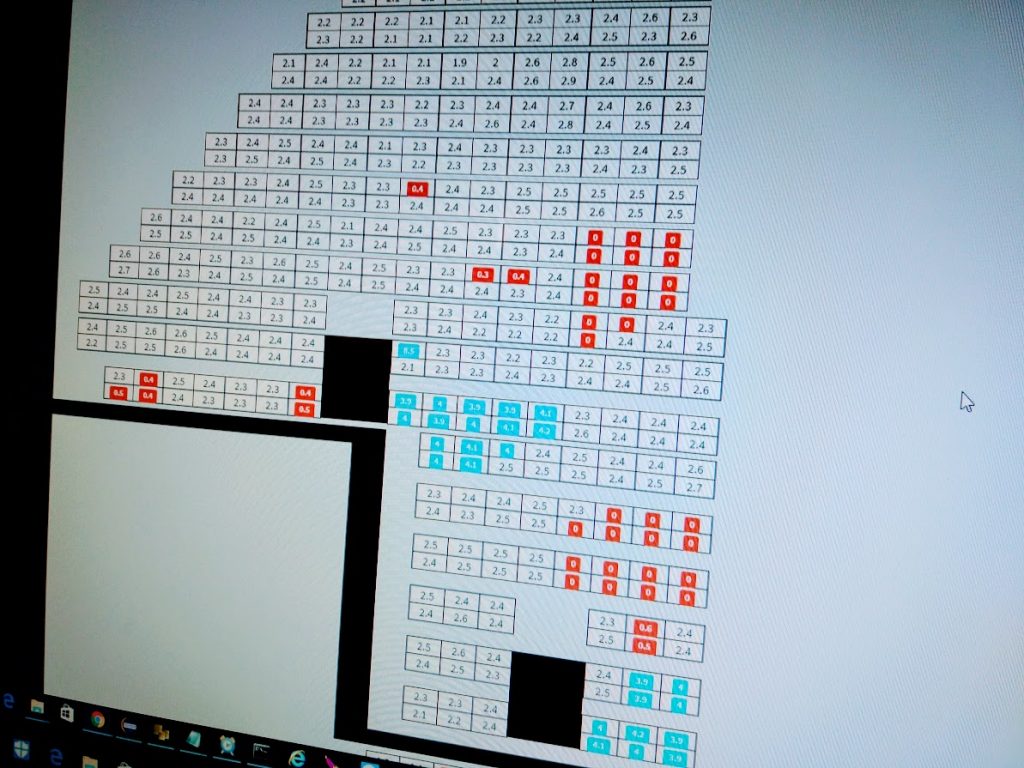

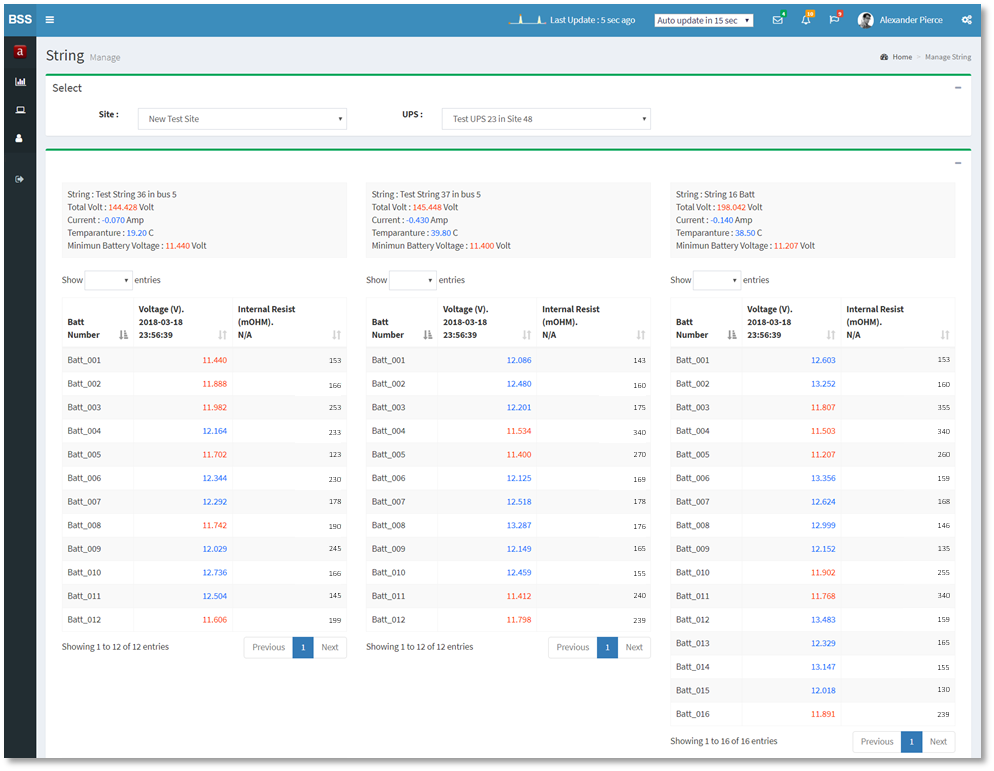

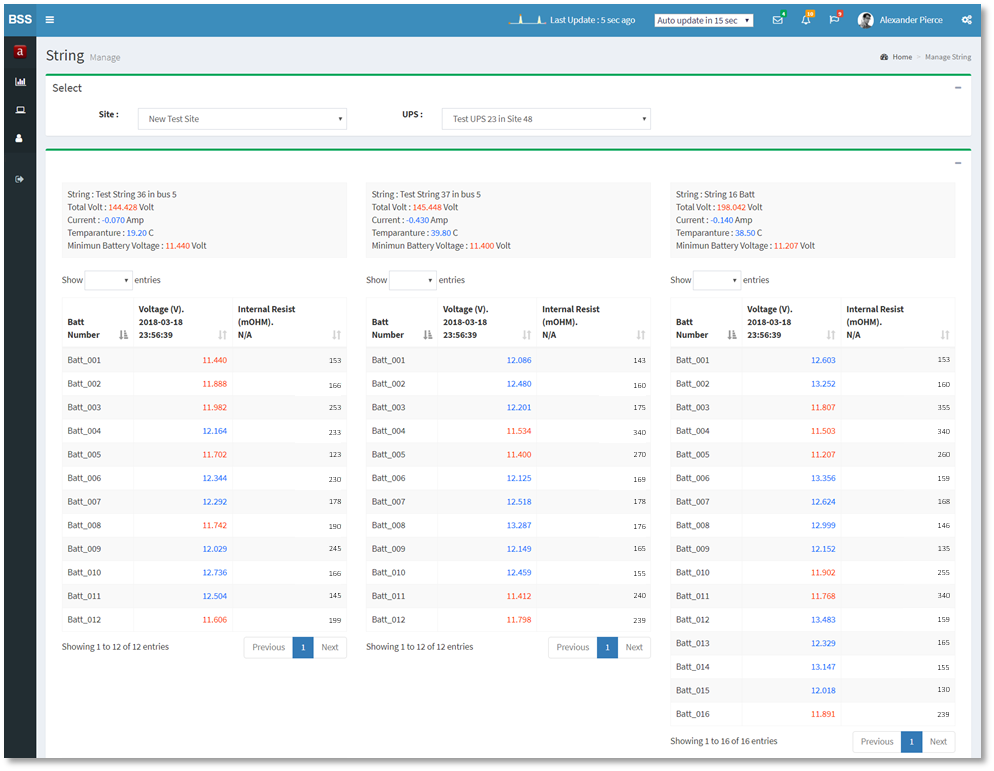

Software Interface : PC Version

Battery Monitoring Software installed in an industrial PC to manage load test schedule, record data and analyze state of health of individual battery using internal resistance information.

Software Features and Functions

Structure Configuration

– Multi-Site Management

– Multi-UPS per Site

– Multi-String per UPS

– Battery Types and Condition

Real-time Monitoring

– Charge/Discharge Status

– Individual Battery Voltage

– String Total Voltage

– String Current

– Ambient Temperature

Overall Level Alert

– Power Outage / Discharge Event

– Abnormal Ambient Temperature

– Over Charge/Discharge Current

Individual Battery Alert

– Over Charging Voltage

– Deep Discharging Voltage

– Internal Resistance exceeding threshold

– %Change of Internal Resistance from Initial State

Discharge Curve Analysis

– Discharge curve comparable to the other batteries

– Internal Resistance Trending comparing to threshold

Scheduled Automatic Load Test

– Monthly/Daily Schedule

– Specific day of month

– Specific hour of day

Monitoring Cloud Services

We also provide cloud solution for Battery Monitoring Services.

Why cloud?

– Customers can monitor anywhere anytime over the internet.

– Multiple locations support.

– Maintenance-free software.

– Save initial cost on infrastructure.

– Free new features update.